What are the five most classic applications of machine vision technology?

Machine vision system has greatly improved the degree of automation of mass and sustainable production, and greatly improved the efficiency and product accuracy of industrial production. At present, the use of automation equipment for material distribution, which the use of machine vision system to capture product images, image analysis, output results, and then through the robot will be the corresponding material in a fixed position, so as to achieve intelligent industrial production, modernization and automation.

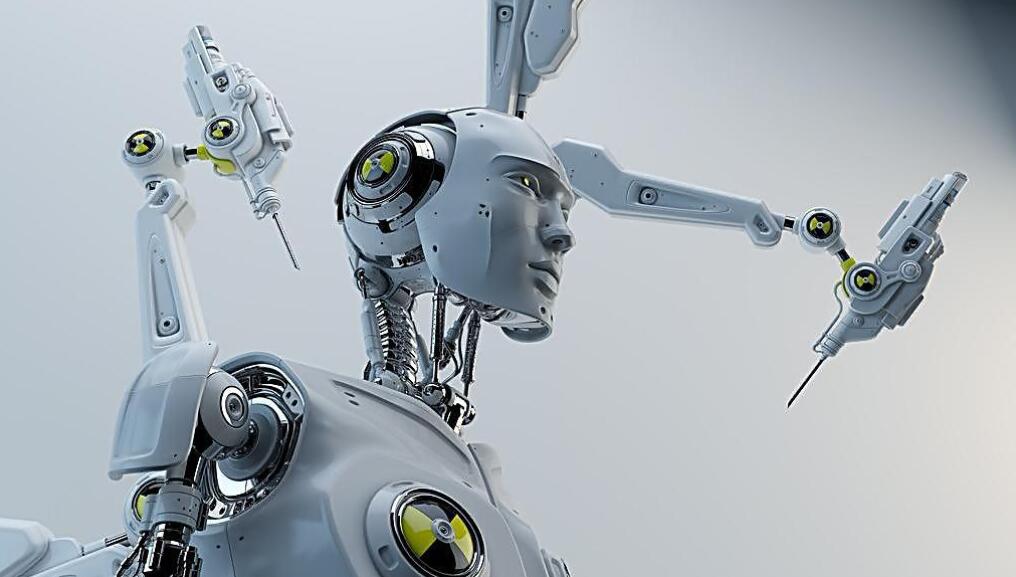

Nowadays, the rapid development of automation technology has set off a wave of enthusiasm, our understanding of machine vision has deepened, everyone's view of it has changed dramatically. With the continuous maturity and progress of machine vision technology, the scope of application is more and more extensive. At present, these five machine vision applications can basically summarize the role of machine vision technology in industrial production.

Machine vision system has greatly improved the degree of automation of mass and sustainable production, and greatly improved the efficiency and product accuracy of industrial production. At the same time, the ability to obtain information and automate processing becomes extremely rapid, providing an effective way for information integration in industrial production.

1. "Object sorting"

In the application of machine vision, object sorting application is based on recognition and detection of a link. Images are processed through machine vision systems and product sorting is combined with the use of robotic arms.

For example, in the old production line, the material was put into the injection molding machine manually, and then the next step was taken.

At present, the use of automation equipment for material distribution, which the use of machine vision system to capture product images, image analysis, output results, and then through the robot will be the corresponding material in a fixed position, so as to achieve intelligent industrial production, modernization and automation.

2. "Image Detection"

In production and life, every kind of product needs to check whether it is qualified, and needs a certificate of inspection. To say that inspection is the most widely used in machine vision, no one should have an opinion.

Before the machine vision is not developed, artificial naked eye detection often encounter a lot of problems, such as accuracy is too low, easy to make mistakes, can not work continuously, easy to fatigue, time-consuming and laborious.

With the wide application of machine vision, the production and detection of products have entered a high degree of automation. In the specific application, common coin character detection, circuit board detection and so on.

Moreover, the detection of RMB coinage process has high precision requirements, many detection equipment and complex process.

In addition, there are machine vision positioning testing, beverage bottle cap production is qualified, whether there is a problem, product barcode character testing and recognition, glass bottle defect testing and medicinal glass bottle testing. The medical field is also one of the main application areas of machine vision.

3, object measurement"

The non-contact measurement technology is the biggest feature of machine vision industrial application, because the non-contact no wear, so avoid the potential secondary damage caused by contact measurement.

Machine vision, as the name suggests, is the ability to "see" mechanical devices, just as people have eyes to see objects.

Machine vision measurement objects do not need to contact products like traditional manual, but its high precision, high speed performance is the same, not only for the product without wear, but also to solve the possibility of secondary damage to the product.

This has significantly improved the level of precision instrument manufacturing. It is widely used for measuring Luoding thread, twist drill, IC component pins, automotive parts and plug-ins.

4. "Visual Positioning"

What is "visual orientation"? Visual positioning can accurately detect the product and confirm its position.

In the field of semiconductor manufacturing, the adjustment and pickup of chip position information is very difficult, machine vision can solve this problem, because the need to accurately pick up the chip and binding, which is also the reason why visual positioning has become the most basic application of machine vision industry.

5. Image Recognition"

Image recognition, simply put, is the use of machines for visual processing, analysis and understanding of images, recognition of various objects and targets, the function is very powerful.

The most typical image recognition would be to identify QR codes. Qr codes and bar codes are very common bar codes in our life. In the production of goods, manufacturers store large amounts of data in small QR codes and manage and trace products in this way.

With the application of machine vision image recognition more and more widely, the bar code on the surface of various materials becomes very easy to be recognized, read and detected, thus greatly improving the level of modernization, production efficiency and production costs.

Die Produkte, an denen Sie interessiert sein könnten

|

916 | SWITCH PB 16MM RED LED | 2376 More on Order |

|

1194 | SWITCH PUSHBUTTON SPST-NO BLUE | 8334 More on Order |

|

475 | SWITCH PUSHBUTTON SPST-NO GRN | 5400 More on Order |

|

473 | SWITCH PUSHBUTTON SPST-NO RED | 6300 More on Order |

|

1185 | SWITCH PUSHBUTTON SPST-NO RED | 7686 More on Order |

|

1293 | SENSOR HUMID/TEMP 5V I2C 2% MOD | 7740 More on Order |

|

628 | STARTER PK EL PANEL 10X10CM WHT | 3996 More on Order |

|

415 | ELECTROLUMINESC STRIP 100CM AQUA | 6066 More on Order |

|

2556 | DIGITAL RGB LED WEATHERPROOF STR | 2232 More on Order |

|

3803 | ADDRESS LED 64X32 FLEX RGB MATRX | 4716 More on Order |

|

2824 | ADDRESS LED STRIP SERIAL RGBW 5M | 4788 More on Order |

|

1614 | ADDRESS LED MATRIX I2C WHITE | 6588 More on Order |

|

2873 | ADDRESS LED RING 1/4 SER RGBW | 8316 More on Order |

|

2541 | ADDRESS LED STRIP SERIAL RGB 1M | 7560 More on Order |

|

2958 | ADDRESS LED STRIP SERIAL RGB 1M | 4248 More on Order |

|

1632 | ADDRESS LED MATRIX I2C GREEN | 5508 More on Order |

|

2294 | ADDRESS LED MATRIX SERIAL RGB | 6678 More on Order |

|

607 | ADDRESS LED MATRIX RGB | 5130 More on Order |

|

1506 | ADDRESS LED STRIP SERIAL RGB 1M | 6288 More on Order |

|

2759 | ADDRESS LED DISCR SER RGBW 1=10 | 17796 More on Order |

|

188 | GRAPHIC KS0108 LCD 128X64 + EXTR | 4392 More on Order |

|

1820 | LED MATRIX 8X8 SQUARE GREEN | 2268 More on Order |

|

2947 | LED CHARLIEPLEXED MATRIX - 9X16 | 7146 More on Order |

|

1399 | RGB 7-SEGMENT 1"" COMMON ANODE | 7488 More on Order |