How can thin film capacitors improve OBC performance?

Thin film capacitors in new energy vehicles are a key electronic component, and they are commonly used in functions such as filtering, coupling, decoupling, energy storage, and frequency regulation in circuits. In new energy vehicles, the stability, high temperature resistance and long-term reliability of thin film capacitors are particularly important because they must be able to work continuously in harsh automotive environments.

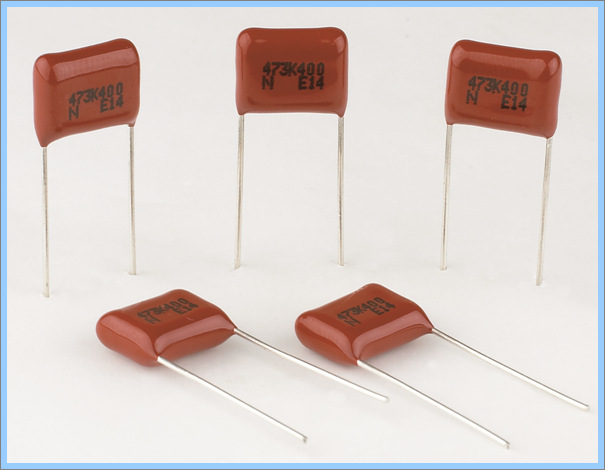

Thin film capacitors, as an excellent alternative to electrolytic capacitors, are now used in large quantities in new energy vehicles and have attracted much attention. The thin film capacitor essentially uses a metal foil as an electrode, overlaps it with a plastic film such as polyethyl ester, polypropylene, polystyrene or polycarbonate from both ends, and is wound into a cylindrical structure of the AD830JR capacitor.

At the same time, thin-film capacitors exhibit the advantages of higher voltage resistance, lower ESR, and non-polarity, which makes the design of thin-film capacitor-based systems more simplified and can reliably function in harsh environments.

New energy vehicles need to take into account seismic, high temperature, high voltage and high current, high reliability and many other requirements, although the electrolytic capacitor capacity is enough but other aspects have been unable to meet, and these characteristics of thin film capacitors just fit the scene of electric vehicles, especially OBC, DC/DC needs, thin film capacitors also become the ideal device in the process of automotive electrification upgrade.

The most representative application is OBC, from EMI filtering to PFC, to DC-link, to LLC resonance stage, and the final output, all require the application of thin film capacitors.

OBC (On-Board Charger) is an important component in new energy vehicles, which is responsible for converting alternating current (AC) to direct current (DC) in order to charge the battery of an electric vehicle. The performance of OBC directly affects the charging efficiency, charging speed and the safety performance of the vehicle.

In OBC applications, thin-film capacitors need to pay special attention to the three characteristics of self-healing, failure open circuit and low dissipation coefficient. In particular, self-healing, good self-healing ability means that the device has strong overvoltage resistance and good high frequency. Self-healing means that the dielectric of the film capacitor can repair itself and return to normal working state after being broken down.

Thin film capacitors play a crucial role in OBC, especially in power factor correction (PFC) and DC-DC converter modules. Here are a few aspects of how thin film capacitors can improve OBC performance:

1, power factor correction (PFC) : In order to improve the efficiency of power utilization, OBC will use PFC circuit to optimize the input current waveform, so that it is synchronized with the input voltage waveform, reducing the ineffective power. Thin film capacitors are used here for filtering, which can reduce the harmonics of the current and improve the power factor, thereby improving the overall energy efficiency.

2, DC-DC converter: In OBC, the DC-DC converter is responsible for converting the high-voltage direct current output of the PFC circuit into low-voltage direct current suitable for battery charging. In this module, the film capacitor is used for energy storage and filtering, ensuring voltage stability, reducing the ripple of the output voltage, and improving the conversion efficiency and stability.

3, thermal stability: the working environment temperature of new energy vehicles varies widely, and the film capacitor has good thermal stability and can maintain the same performance in a wide temperature range, which is essential to ensure the long-term reliable operation of OBC.

4, long-term reliability: Film capacitors have longer life and better aging characteristics than other types of capacitors (such as electrolytic capacitors), which helps to improve the overall reliability of OBC and reduce maintenance costs.

5, size optimization: With the advancement of technology, the volume and weight of film capacitors are continuously reduced, which makes OBC more compact, reduce the weight of the vehicle, and improve the energy efficiency and power performance of the vehicle.

6, electromagnetic compatibility (EMC) : Thin film capacitors can reduce electromagnetic interference, improve the electromagnetic compatibility performance of OBC, ensure the normal operation of on-board electronic systems, and comply with strict automotive industry standards.

In summary, thin film capacitors significantly improve the performance of OBC by improving the filter effect of the circuit, optimizing thermal stability, extending life, reducing volume, and enhancing electromagnetic compatibility, thereby improving the overall performance and user experience of new energy vehicles. With the continuous development of the new energy vehicle industry, the performance requirements for thin film capacitors will also be higher and higher.

Die Produkte, an denen Sie interessiert sein könnten

|

AIRD-03-271K | FIXED IND 270UH 4.5A 110 MOHM TH | 6390 More on Order |

|

ACM-31-261M-T | CMC 310MA 2LN 260 OHM SMD | 23466 More on Order |

|

AMPMEEB-16.0000T3 | MEMS OSC XO 16.0000MHZ CMOS SMD | 2934 More on Order |

|

AMPMAFD-3.6864T3 | MEMS OSC XO 3.6864MHZ CMOS SMD | 3454 More on Order |

|

AMPMGGA-24.5000T | MEMS OSC XO 24.5000MHZ CMOS SMD | 5760 More on Order |

|

AMPMGDB-74.2500T | MEMS OSC XO 74.2500MHZ CMOS SMD | 4698 More on Order |

|

AMPMGDA-18.4320T | MEMS OSC XO 18.4320MHZ CMOS SMD | 5202 More on Order |

|

AMPMDDD-36.8640T | MEMS OSC XO 36.8640MHZ CMOS SMD | 5544 More on Order |

|

AMPMEFA-15.0000 | MEMS OSC XO 15.0000MHZ CMOS SMD | 5652 More on Order |

|

AMPMDEA-30.0000 | MEMS OSC XO 30.0000MHZ CMOS SMD | 3996 More on Order |

|

AMPMAGC-31.2500 | MEMS OSC XO 31.2500MHZ CMOS SMD | 5976 More on Order |

|

ASTMUPCD-33-24.576MHZ-LY-E-T3 | MEMS OSC XO 24.5760MHZ LVCMOS | 8766 More on Order |

|

ASCO1-64.000MHZ-EK-T3 | XTAL OSC XO 64.0000MHZ CMOS SMD | 7380 More on Order |

|

ASGTX-C-20.000MHZ-2-T | XTAL OSC VCTCXO 20.0000MHZ LVCMO | 5490 More on Order |

|

AX5DBF1-987.6543T | OSC XO 987.654321MHZ 2.5V LVDS | 6588 More on Order |

|

AX7PBF1-500.5000C | XTAL OSC XO 500.5000MHZ LVPECL | 2574 More on Order |

|

AX5HBF1-368.6400C | OSC XO 368.64MHZ 2.5V HCSL | 7164 More on Order |

|

ASFLMPC-33.000MHZ-Z-T | MEMS OSC XO 33.0000MHZ CMOS SMD | 6660 More on Order |

|

ASTMHTD-16.000MHZ-XR-E-T | MEMS OSC XO 16.0000MHZ LVCMOS | 8892 More on Order |

|

ABM13W-32.0000MHZ-7-B1G-T5 | CRYSTAL 32MHZ 7PF SMD | 5832 More on Order |

|

ABM11W-44.0000MHZ-4-B2U-T3 | CRYSTAL 44.0000MHZ 4PF SMD | 4104 More on Order |

|

ABM11W-33.3300MHZ-8-B2U-T3 | CRYSTAL 33.3300MHZ 8PF SMD | 4932 More on Order |

|

ABM10W-36.0000MHZ-7-K1Z-T3 | CRYSTAL 36.0000MHZ 7PF SMD | 6192 More on Order |

|

ABM10W-22.5792MHZ-6-J1Z-T3 | CRYSTAL 22.5792MHZ 6PF SMD | 3114 More on Order |